Powerful homemade lawn mower for the village with their own hands

I made this powerful lawnmower myself for the village, there is always a lot of high grass, which is not rational to fight with the usual manual trimmer. This animal mows down everything, tough grass, small trees, levels of hills, covered with moles, and even turns old bricks out of the ground.

The design of the homemade lawn mower was very successful. The mower does not make noise like a gasoline, the only negative & nbsp; is that you have to carry an electric wire, but this is nonsense.

The lawn-mower works from a network of 220 volts. I have long been lying idle electric asynchronous motor from a woodworking machine, motor power 2.2 kW, 380 volts, 1420 rev / min. Such a motor is of course not required if you have low grass and you mow regularly. The motor itself is very heavy and it is difficult to roll it on the ground, it is better to find a 220 volt motor to 1 kW, it will be half the size. The motor is fixed on the frame with the help of iron corners fastened with tin kerchiefs. For starting the motor, capacitors are needed, I have few of them, so the motor does not work at full capacity. On the handle secured the mounting box in which the circuit breaker is placed.

I made a frame for the mower from the remains of an iron corner with a 25 mm shelf, only 4 pieces, they are twisted with M8 bolts and nuts. A sheet of 4 mm plywood is clamped between the corners and a strip of the same plywood is screwed behind to protect the legs, but it is better to put a piece of tin there.

Riding lawn mower on 4 wheels from the pram, they rotate on the bolts M10. It’s good that I took big wheels, it would be impossible to ride small ones. He took a pen from the old stroller, on which they carry bags, the handle is a bit short, in the future I will replace it with something else.

A pulley is dressed on the motor shaft, an iron plate 40 cm long with a section of 40 * 4 mm is bolted to the pulley with M8 bolts. On the edge of the plate are made notches with the help of fortune. Later I will change the knife, I will put 50 cm in length, the swath will be wider, the engine power will be enough for this. There is a problem with winding long grass on the shaft, this is solved by installing two plastic glasses that will fit into each other, this will be done later.

As this homemade electric lawn mower mows, look at the video. The first exit turned out to be very successful; about 10 acres of tough, & nbsp; high grass were mown with tree branches and the remains of bricks from old flower beds.

Add comment

Random DIY

-

This device helped me to saw a bundle of rolled metal at an angle of 90 degrees without effort.

-

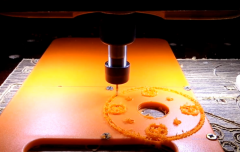

I made this CNC machine myself in 2015, videos of the same year. For a long time I was asked to make a video on the assembly of this machine, later my hard drive broke, by some miracle I found some materials on this machine on another medium. After almost 4 years I will publish the materials, as I did with my own hands a CNC machine tool from the available materials.

-

It’s 2024, stores are already selling robotic vacuum cleaners, and you can even buy used ones for a reasonable price. And I still dream of assembling my own robot vacuum cleaner with my own hands.

-

I had a new passion - brooches of felt. Such small, lovely - they can be an independent gift or an excellent surprise to the main.

-

The eternal problem, which wire to connect :)