Saw at an angle (device for Bulgarians, Fortune, USM)

This device helped me to saw a bundle of rolled metal at an angle of 90 degrees without effort.

Now I'm building a second CNC machine, the working field will be 1050 * 1050 mm. For the frame, I needed to cut a profile pipe and corners. I had a Bulgarian, but I did not want to saw manually, this would lead to big errors. For half an hour I built a simple device that allowed me to cut the metal exactly at an angle of 90 degrees.

Comments [2]

Add comment

Random DIY

-

There was a mountain of packages that occupied a whole drawer in the kitchen. And now there is a small box with packages. The whole secret is to roll packages with a simple device.

-

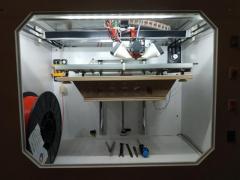

Today, instead of round guides, the printer received square, using a conventional aluminum profile tube with a cross section of 20 * 20 mm. Bearings roll along the pipe 623zz. All plastic parts were printed on the same printer before it was altered.

-

This cool garland is assembled according to the design of Alex Hyvera using Arduino and an address LED strip. The garland has many interesting effects, a running text, several games and the ability to control all this from a mobile phone.

-

Candles in the shape of eggs perfectly complement the Easter holiday. The unusual shape of the candle very much like the grandmother.

-

I need a tachometer to calculate some mechanisms. For example, to calculate the speed of a robot vacuum cleaner, you need to know the rotation speed of the electric motor and, based on this, calculate the gear ratio of the gearbox.

Super job!

lmgHAcLckMZlQGxVZpZdP