Plastic milling on homemade CNC # CNC1000

I made this CNC machine myself in 2015, videos of the same year. For a long time I was asked to make a video on the assembly of this machine, later my hard drive broke, by some miracle I found some materials on this machine on another medium. After almost 4 years I will publish the materials, as I did with my own hands a CNC machine tool from the available materials.

These were successful doubles, the first attempts to mill plastic on the CNC. Two-way milling cutter for wood, for plastic it is better to use a single-cutter, because plastic melts and sticks to the milling cutter. If plastic chips stick to the mill, then the mill will most likely break or turn black from overheating.

Add comment

Random DIY

-

It’s 2024, stores are already selling robotic vacuum cleaners, and you can even buy used ones for a reasonable price. And I still dream of assembling my own robot vacuum cleaner with my own hands.

-

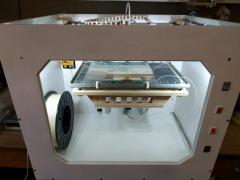

I present to your attention a homemade 3d printer. Assembled from plywood, aluminum, plastic and Arduino. This printer is unique in that its kinematics is peeped from Ultimaker, but done with quality modifications.

-

The idea of assembling a homemade CNC machine appeared long ago. Lack of knowledge and necessary details. Today there is everything!

-

Hello, dear friends! My name is Dmitriy or just Dima :) I'm the creator of the ModelMen.ru site, I did it specifically to collect the most interesting ideas and handicrafts created by myself.

-

I made this powerful lawnmower myself for the village, there is always a lot of high grass, which is not rational to fight with the usual manual trimmer. This animal mows down everything, tough grass, small trees, levels of hills, covered with moles, and even turns old bricks out of the ground.