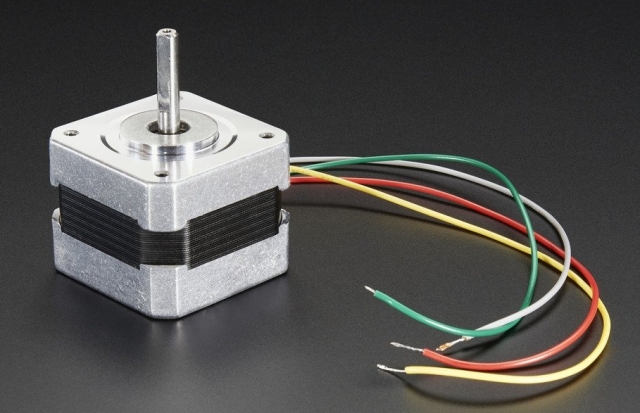

How to connect a stepper motor to the driver, color coding of wires

The eternal problem, which wire to connect :)

OPTION 1

Motor Nema17

DriverA4988 Polulu

1A - green

1B - black

2A - blue

2B - red

OPTION 2

Motor Nema17

Driver DM420A

A + black

A - green

B + red

B - blue

A SPECIAL CASE

There are such motors Nema17 , whose wires do not have the same color as all :)

Marking for such wires I write in brackets:

A + black (red)

A - green (green)

B + red (yellow)

B - blue (blue)

Comments [1]

Add comment

Random DIY

-

I need a tachometer to calculate some mechanisms. For example, to calculate the speed of a robot vacuum cleaner, you need to know the rotation speed of the electric motor and, based on this, calculate the gear ratio of the gearbox.

-

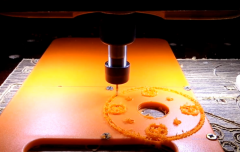

I made this CNC machine myself in 2015, videos of the same year. For a long time I was asked to make a video on the assembly of this machine, later my hard drive broke, by some miracle I found some materials on this machine on another medium. After almost 4 years I will publish the materials, as I did with my own hands a CNC machine tool from the available materials.

-

The 3D model of the fan is very simple, easily wound on a collet clamp. I put it on my CNC machine. The first launch proved to be very good, all the chips are scattered to the sides, clean under the cutter.

-

I made this powerful lawnmower myself for the village, there is always a lot of high grass, which is not rational to fight with the usual manual trimmer. This animal mows down everything, tough grass, small trees, levels of hills, covered with moles, and even turns old bricks out of the ground.

-

This is my first CNC machine assembled with my own hands from available materials. The cost price of the machine is about $170.

Thanks for this :)