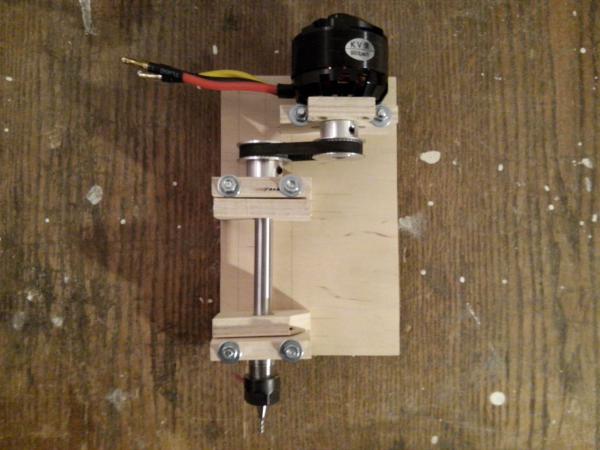

Spindle for homemade CNC

The idea of assembling a homemade CNC machine appeared long ago. Lack of knowledge and necessary details. Today there is everything! This is the first article in which I will show how I assembled the spindle. Electronics and the frame will be described elsewhere.

First of all, I assembled a spindle with a brushless motor. It was certainly possible to buy a ready-made router, but it has its drawbacks:

- Noise

- Brushes

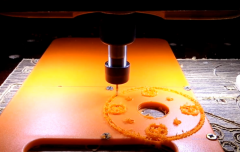

My router does not know-how, there are already such constructions on the Internet, I just repeated it and the experiment turned out to be successful. I have not conducted any serious tests so far, but the first launch and the attempt to milled the plywood were successful.

Brushless motor Aeolian C5045 KV900 (35$)

Rotation speed: 900 (KV) rpm / volts

DC: 80 amperes

Max. Current: 90 Ampere

Input voltage: 6-28 volts

Max. Performance: 98%

No load current: 2.6 Amps

Internal resistance: 21 m (Omega)

Power: 1185W

Motor, dimensions (diameter x length): 50 mm x 45 mm

To the motor the regulator of turns MYSTERY Fire Dragon 100A

To adjust is still needed servotester

The power supply unit is at 24 volts at least 10 amperes . Update: My motor consumed about 4 amps under load. I do not know why so little, they write that the motor is at 80 amperes. The answer to this question I never found.

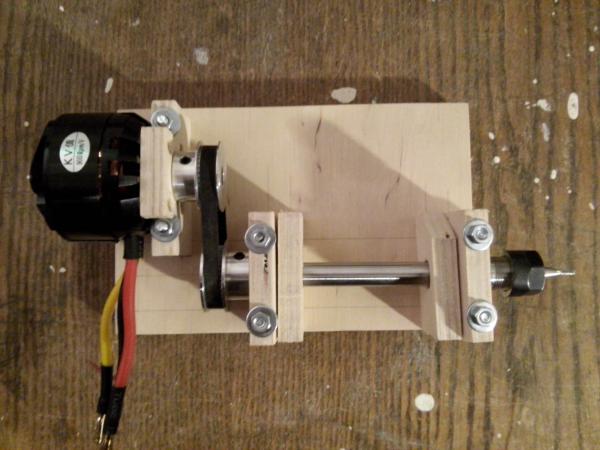

I bought a motor specially with a shaft diameter of 8 mm, here and the bearing is large (it will last longer) and the pulley is easy to find with the same diameter.

I bought a collet cartridge with a shank diameter of 10 mm, although probably now I would buy it with a diameter of 8 mm, it would be simpler, because it was not easy to find a pulley with a diameter of 10 mm and a suitable number and size of teeth. In addition, it is possible to pull out the motor shaft from the motor and insert the shank of the collet chuck, in this case the need for a belt transmission is completely eliminated. In other words, the flywheel of the motor is placed directly on the shank of the cartridge. Although in this case there are drawbacks.

I have a simple design, only a few details of plywood and an hour of time spent on assembly.

The first test was with a battery from a screw driver for 18 volts, the battery is inserted. The belt allows you to get rid of vibration, and if the motor is put on a rubber cushion, the noise will be minimal. From above to the motor it is possible to screw the blades, which will blow it during operation.

The result of the spindle test is positive, in the following articles I will show how I will build a frame for a homemade CNC machine.

Update: My first CNC

Add comment

Random DIY

-

I need a tachometer to calculate some mechanisms. For example, to calculate the speed of a robot vacuum cleaner, you need to know the rotation speed of the electric motor and, based on this, calculate the gear ratio of the gearbox.

-

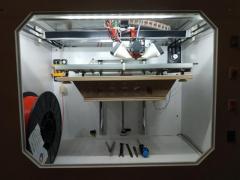

I made this CNC machine myself in 2015, videos of the same year. For a long time I was asked to make a video on the assembly of this machine, later my hard drive broke, by some miracle I found some materials on this machine on another medium. After almost 4 years I will publish the materials, as I did with my own hands a CNC machine tool from the available materials.

-

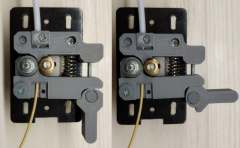

Bowden extruder for a 3D printer with minimal gaps and no extra parts. An eccentric is provided for compressing the spring and releasing the filament rod.

-

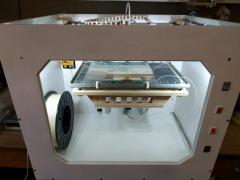

I present to your attention a homemade 3d printer. Assembled from plywood, aluminum, plastic and Arduino. This printer is unique in that its kinematics is peeped from Ultimaker, but done with quality modifications.

-

Today, instead of round guides, the printer received square, using a conventional aluminum profile tube with a cross section of 20 * 20 mm. Bearings roll along the pipe 623zz. All plastic parts were printed on the same printer before it was altered.